All of my opinions are italicized and sources are in blue.

Every company seems to be putting out handheld gaming PCs these days, and Lenovo is next to the plate. The company has announced the Legion Go, its first Windows-powered gaming handheld, which will be available for purchase in October. It has an 8.8-inch QHD Plus screen, an AMD Ryzen Z1 Extreme processor, and a 49.2Wh battery (which is bigger than those of the ROG Ally and the Steam Deck). Oh, and the controllers pop off, which is neat.

While Valve’s Steam Deck tends to be the first product that comes to mind when this category is discussed, the Legion Go seems more like a cross between the Nintendo Switch and Asus’ ROG Ally. For one, with models starting at $699, the Ally is clearly what Lenovo is trying to match on price. But it also, like the Ally, is running old-school Windows and has more controls (a touchpad, primarily) that are tailored toward operating that system.

With controllers attached, the Legion Go is about half a pound heavier than the ROG Ally (and a bit heavier than the Steam Deck). It is a noticeable difference when you pick the device up. Nevertheless, this is something some potential customers will be unhappy about, particularly those who are buying a handheld for frequent travel. The presumable upside of this extra bulk is battery life and the Legion Go has a larger battery compared to other handhelds.

In terms of other specs, the screen has a 2560 x 1600 resolution and a 144Hz refresh rate. Inside, there is 16GB of LPDDR5X RAM and up to 1TB of storage. Ports include a 3.5mm audio combo jack, a USB-Type C (USB 4.0, DisplayPort 1.4, Power Delivery 3.0), and a microSD reader, as well as an additional USB Type-C (same specs as before) on the bottom.

When it comes to gaming, the main problem is Windows. Windows is not optimized to be used with joysticks and no physical keyboard. This is why the Switch and Steam Deck use their own operating system to manage their games. This increases stability but takes a hit to compatibility. The upside to Windows is the ability to play almost any game that was released on Steam, which the Steam Deck could not do with its Linux based OS.

Even if you’re working hand in hand with Microsoft, this is a hard feat to pull off. Lenovo’s competitor Asus, for example, worked closely with Microsoft throughout the ROG Ally’s development to tailor Windows’s UI to the smaller form factor and create distinct controls for desktop use. Despite all this, the Ally controls have still displayed some issues with sensitivity, precision, and bindings, and we ran into a laundry list of situations in our initial testing process where buttons did not do quite what they were supposed to do.

Hopefully, all of these issues are smoothed out before its final release in October.

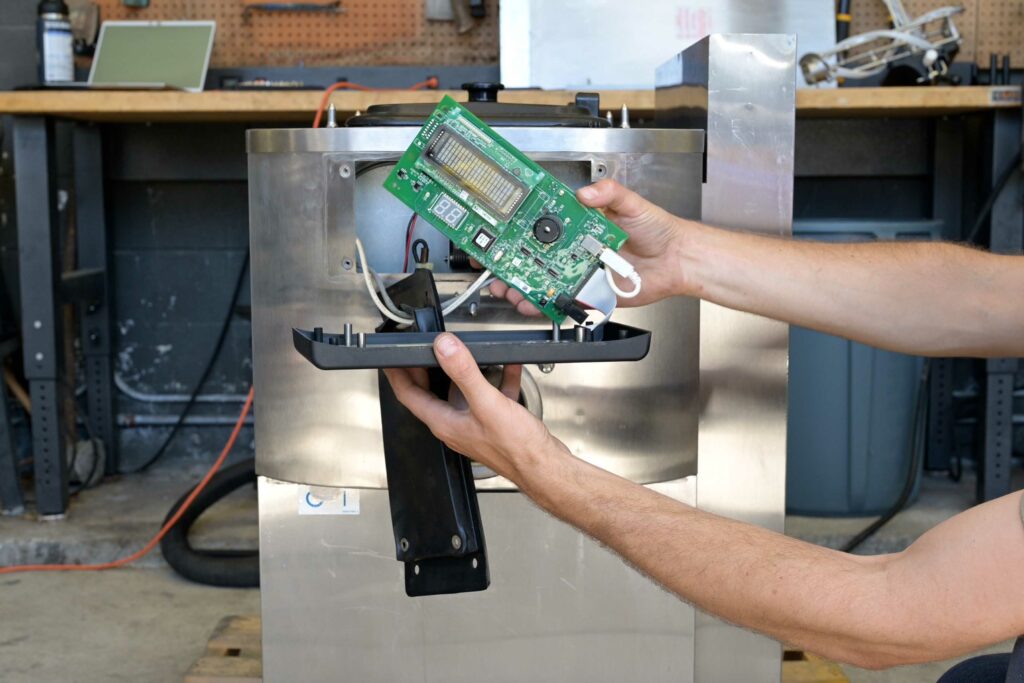

At any given time, about 10% of McDonald’s ice cream machines are broken. To investigate this, iFixIt purchased an ice cream machine (Taylor’s C709) that is mostly identical to the ones found in the restaurant. This revealed some anti-repair measures implemented by Taylor, the sole manufacturer and repair technician for these machines.

The first reason for high down times comes from the machine taking four hours to “warm up”. During that time, the machine threw out error codes that forced iFixIt to refer to the manual. The problem was the manual did not explain the error codes properly. This led to the machine taking way more than four hours to start serving ice cream.

These manuals seem to be intentionally made difficult to understand so franchisees would be forced to call Taylor service technicians. These technicians charge $1,260 per hour to fix these basic machines. Sadly, these charges do not go to the technicians themselves, but rather to the company. 25% of Taylor’s profits come from service technician call outs, so it’s easy to see why Taylor will make error codes complex in order to make more money.

A company named Kytch sought to provide a solution by developing a device that translated error codes into simple instructions. However, Taylor and McDonald’s quickly crushed this initiative, citing unproven “safety hazards.”

When iFIxIt tore down the machine, it revealed a lot of easily replaceable parts: a heat exchanger with copper piping, a motor and belt, and three printed circuit boards. If Taylor were to provide these parts and repair guides to franchises, repair would be simple and cost effective.

In order to accomplish this, iFIxIt is asking Congress to reintroduce the Freedom to Repair Act, which would make repair tools legal, and permanently exempting all repair activities from Section 1201 of the DMCA. For those of you who aren’t copyright law experts: the Digital Millennium Copyright Act (DMCA) has a section (1201) that makes it illegal to bypass software locks on devices, even to repair them.

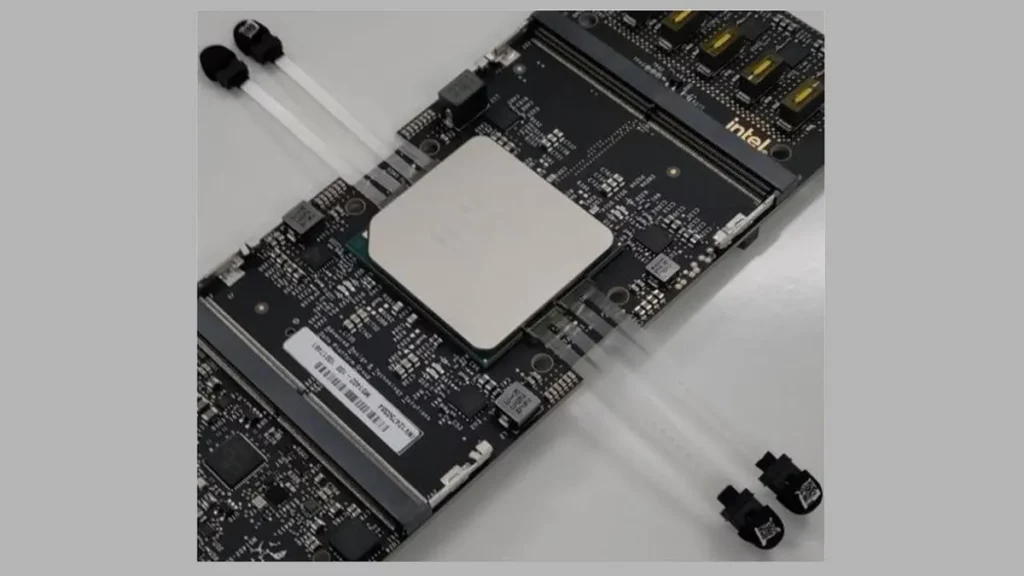

Intel unveiled its first direct mesh-to-mesh photonic fabric at the Hot Chips 2023 chip conference, highlighting its progress towards a future of optical chip-to-chip interconnects that are also championed by the likes of Nvidia and Ayar Labs. However, the eight-core 528-thread chip that Intel used for the demonstration stole the spotlight due to its unique architecture that sports 66 threads per core to enable up to 1TB/s of data throughput. Surprisingly, the chip consumes only 75W of power, with ~60% of the power being used by the optical interconnects, but the design could eventually enable systems with two million cores to be directly connected with under 400ns latency.

Intel’s PIUMA (Programmable Integrated Unified Memory Architecture) chip is part of the DARPA HIVE program that focuses on improving performance in petabyte-scale graph analytics to unlock a 1000X improvement in performance-per-watt in hyper-sparse workloads. Ayar Labs worked with Intel on the optical subsystem.

Surprisingly for an x86-centric company like Intel, the test chip utilizes a custom RISC architecture for streamlined performance in graph analytics workloads, delivering an 8X improvement in single-threaded performance. The chip is also created using TSMC’s 7nm process, not Intel’s own internal nodes.

The promise of optical interconnects has fueled an intensifying amount of research as the industry looks to future data transport methods that offer superior bandwidth, latency, and power consumption characteristics compared to traditional chip-to-chip communication techniques. While mainstream deployments of optical chip interconnects remain on the horizon, specialized implementations, like those championed by Intel, Nvidia, and Ayar Labs, are nearing readiness for large-scale deployments in the near future.

Helen Marie Plourde, an 86-year-old Minnesota resident, just spent over a month without home Internet and phone service because CenturyLink failed to fix a problem that began in July.

CenturyLink didn’t show up for scheduled appointments at her home in Saint Paul, August 24, one day after the latest missed service appointment. Another appointment was scheduled for August 28, but she was skeptical that it would actually happen.

“I’ll believe it when I see them,” Plourde said.

Plourde buys broadband through Velocity Telephone, which resells CenturyLink fiber service in her area and acts as an intermediary between customers and CenturyLink for repairs. Velocity told us that it set up CenturyLink appointments for Plourde on August 10, August 17, and August 23, but no CenturyLink technicians showed up to any of the appointments.

CenturyLink sprang into action only after Ars Technica contacted the company’s media relations team on Thursday night. A CenturyLink technician went to Plourde’s home on Friday morning and fixed a line problem on a nearby street, restoring her Internet and VoIP phone service.

Velocity’s VP of operations, Todd Mueller, told Ars that “many of our customers purchase our resold CenturyLink services specifically because they prefer interfacing with our staff rather than CenturyLink directly, but unfortunately, we have little agency to directly affect Helen’s repair as we do not control the physical service.”

Pat Gelsinger, chief executive of Intel, said that the company is accelerating the buildout of its 20A and 18A-capable fab in Arizona as it preps to ramp up its chips and chips manufacturing by its Intel Foundry Services clients using these technologies. In addition, he said that with its 18A (1.8nm-class) fabrication technology being production-ready in the second half of next year, the firm will formally regain process technology leadership in 2024.

To recoup development costs of its 18A and 20A process technologies — which will enter high-volume production 18 – 24 months ahead of competing production nodes from TSMC and Samsung Foundry — Intel must gain third-party customers. Apparently, the company is succeeding in this. According to Gelsinger, at least one of IFS’s customers is so confident of Intel’s 18A fabrication technology that it has made a considerable prepayment to allocate capacity.

“I have begun a process to accelerate the buildout of Arizona, right, and based on that customer prepay,” the head of Intel said (via SeekingAlpha). “[…] So we are accelerating our construction build there. We will accelerate the capacity buildup that we have in Arizona.

Gelsinger would not say who the customer is. Still, the company has formally confirmed that it would make a custom 5G infrastructure system-on-chip for Ericsson and signed a pact with MediaTek, which will use its leading-edge nodes in the coming years. Of course, a client might prefer not to announce its 18A engagement publicly.

Meanwhile, the TSMC microchip plant in Phoenix has pushed back plans to start manufacturing to 2025, blaming a lack of skilled labor. It is trying to fast-track visas for 500 Taiwanese workers. Unions, meanwhile, are accusing TSMC of inventing the skills shortage as an excuse to hire cheaper, foreign labor. Others point to safety issues at the plant